A Few Things You Should Know about Water Wells

by Pure Water Annie

If you get your water from a private water well, like it or not, you’re a water plant superintendent.

Most well pumps are of two types: jet pumps, which are used only on relatively shallow wells, and submersible pumps.

Since submersible pumps are most common, that’s what I’m going to concentrate on

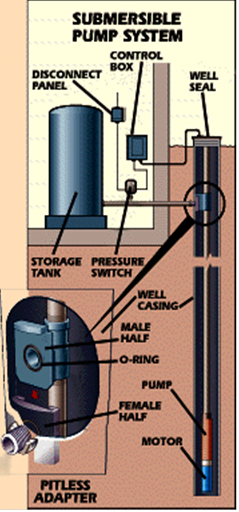

A typical submersible pump is a long cylindrical shape that fits inside the well casing. The bottom half is made up of a sealed pump motor that is connected to the above-ground power source and controlled by electrical wires.

In modern installations, the well casing outside the home is connected to the plumbing system by a pipe that runs beneath the ground to the basement (if there is one).. This horizontal pipe joins the well pipe at a connector called apitless adapter. The function of the adapter is to permit access to the pump and well piping through the top of the well casing, while routing water from the pump into the plumbing system.

While submersible pumps are more efficient than jet pumps in delivering more water for the same size motor, pump or motor problems will necessitate pulling the unit from the well casing–a job that’s best left to a pro. However, submersibles are known for their reliability and often perform their role 20 to 25 years without servicing. Submersible pumps may also be used in shallow wells. However, silt, sand, algae and other contaminants can shorten the pump’s life.

No matter what kind of system you have, the components on the output side of all pumps are similar.

Pumps are not intended to run continuously, and they don’t start each time you open a tap or flush the toilet. In order to provide consistent water pressure at the fixtures, the pump first moves water to a storage tank. Inside a modern tank is an air bladder that becomes compressed as the water is pumped in. The air pressure in the tank is what moves the water through the household plumbing system.

When the pressure reaches a preset level, which can be anywhere from 40 to 60 psi, a switch stops the pump. As water is used in the home, pressure begins to decrease until, after a drop of about 20 psi, the switch turns on the pump and the cycle is repeated. You’ll find the pressure gauge mounted on the tank with wires leading to the switch that controls the pump.

The picture above is from a Popular Mechanics article on well pumps. You can see jet pump illustrations there as well.

Typical air pressure settings for well tanks are 30 to 50 or 40 to 60. What this means is that with a 30/50 setting, for example, the pump comes on to refill the tank when tank pressure drops to 30 psi, and the pump shuts off when the pressure in the tank reaches 50 psi.

In most cases, tank pressure is adjustable and can be controlled with the Pressure Switch in the picture.

If you’re installing a water treatment device such as a softener or backwashing filter, it always goes downstream of the well’s pressure tank. There are a few exceptions. Chemical feed pumps and venturi air injection devices, for example, are installed between the well and the pressure tank.

Although many wells produce excellent water which requires little if any treatment, most well water requires some modification. Some of the most common problems are iron, manganese, hardness, hydrogen sulfide (rotten egg odor), excessive sediment, low pH, and bacteria. Among the most commonly used treatment devices are ultraviolet lamps (bacteria and cysts), sediment filters (sand and other sediment), granular carbon (taste/odor/color improvement, hydrogen sulfide reduction), backwashing media filters (iron, manganese, excessive sediment), aeration, chlorination, hydrogen peroxide, ozonation (pretreatment for iron and sulfide reducing filters), and chemical feed pumps (to control bacteria, raise pH, pretreat for iron removal). These, of course, are only a few of the many devices that can be used to treat well water problems.

What You Need to Know About Your Well

First, every well owner should have a reasonably comprehensive water test to determine the nature of the water. Many problems, like hardness, odor, and iron, are apparent, but a high quality test is needed to confirm and quantify such issues. Two parts per million iron can be treated quite differently from 12 parts per million. And the most urgent problems of all, like bacteria or high levels of arsenic or pesticides, are not apparent but must be discovered by testing.

If you’re going to purchase treatment equipment, especially a backwashing filter or a water softener, for your well, you also need to know how many gallons per minute your well pump is capable of producing. Backwash runs require a sustained flow of several gallons per minute. For example, a typical residential-sized iron filter may require a ten minute backwash and a ten minute rinse at the rate of five to seven gallons per minute. If your well pump will produce only 4, the filter with become overloaded with iron and fail. You can’t rely on the GPM rating of the well pump. You need to know the actual gallons per minute that the well will put out.

Here’s a simple method to find out your well’s output capacity.

Determining the GPM Output of a Water Well

Turn off all taps and water-using appliances in the home.

Find an outdoor spigot in a place that will allow you to observe your well pump’s activity. You’ll need to know when the pump turns on and off. The output capacity of the spigot itself doesn’t matter.

Run water from the spigot until the pump comes on, then close the faucet and let the pump fill the tank and shut off.

With the tank now full, find a container, or multiple containers (e. g. 5-gallon buckets) that will allow you to measure the content of your well tank. Turn on the spigot and catch the water until the pump comes on.

When the pump comes on, immediately close the faucet and time the seconds it takes for the pump to turn off. (This means that the tank is full.)

Now you know the amount of water the tank holds and the number of seconds it takes to refill it. You can determine the well pump’s gallon-per-minute capacity by using the following formula:

Gallons collected, divided by seconds it took to refill the tank, multiplied by 60. (You multiply by sixty to convent the seconds to minutes, because your answer needs to be in gallons per minute.)

For example, if you collected 15 gallons and it took 75 seconds for your pump to refill the tank, your equation would look like this: (15/75)X60 = 12 GPM.

If you collected 18 gallons and it took 55 seconds for your pump to shut off, the formula would be: (18/55) X 60 = 19.6 GPM.

Pure Water Annie’s article was originally published in the Pure Water Occasional’s December 2011 issue.

![pwanniemedium[1]](http://www.purewatergazette.net/blog/wp-content/uploads/2012/05/pwanniemedium1.jpg)