The Advantages of Parallel Installation of Backwashing Water Filters

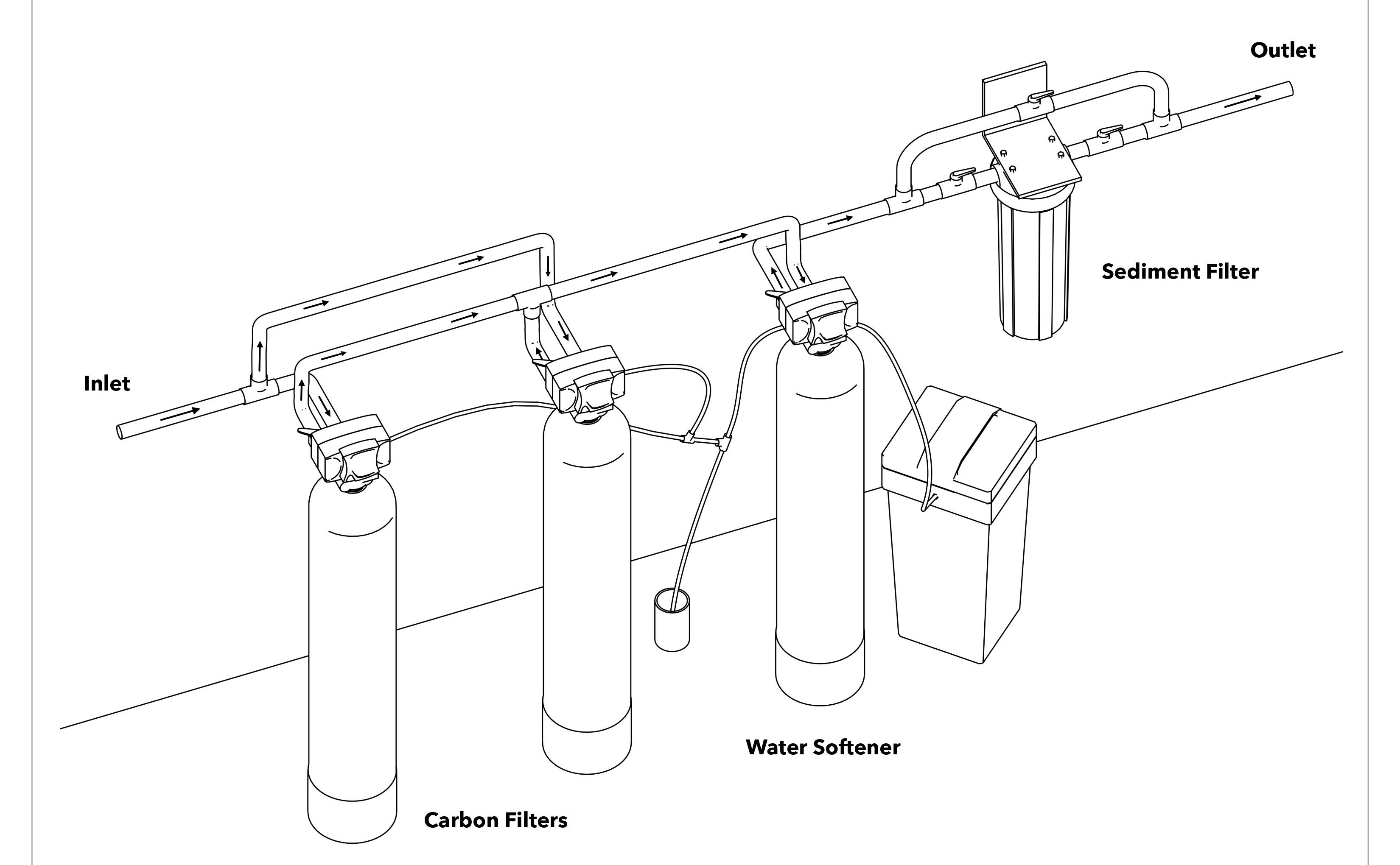

The illustration shows two carbon backwashing filters installed in parallel so that each filter gets half of the treatment stream.

We have long been advocates of parallel installation of two or more cartridge-style filters to achieve higher service flow, to lengthen cartridge life, and to improve overall effectiveness of the filters. Parallel installation also works well with larger backwashing filters.

The challenge in sizing backwashing filters for residential applications is that the filter must be large enough to support sufficient service flow to the home but small enough to fit the space available and to be regenerated on the amount of water available. With filters for challenging contaminants like iron and manganese, the filter often needs more gallons per minute to regenerate itself than it is capable of treating. For example, a well that puts out only six gallons per minute usually cannot support an iron filter that will treat six gallons per minute because backwashing the filter requires more than six gallons per minute. Challenges like this can often be overcome by installing two small filters side by side rather than a single larger filter.

Parallel installation means splitting the water line in half so that each of two filters handles only half of the service flow to the home, then bringing the two lines of treated water together. In the system illustrated above, the carbon filters each get half of the water stream at half the flow rate. If the treatment stream is flowing at five gallons per minute, each filter has to process only 2.5 gallons per minute. The filters then backwash separately so that each gets the full water stream that the well is capable of.

Here are some common situations where two side-by-side filters work better than a single larger filter.

Space limitations. — In a basement or crawl space with limited height, where a 52″ tall filter holding two cubic feet of media won’t quite fit, you can use two 48″ filters each holding one cubic foot.

Water limitations. If the water source won’t put out enough water to backwash the iron filter you need, you can use two smaller filters and set them up to backwash at different times. Each filter has to process only half of the service flow but gets the well’s full output for backwash. (It is common for a backwashing filter to need a higher flow rate for backwash than it is capable of processing for service flow.)

Ease of upkeep. A single large backwashing filter can be too heavy for installation or for a media change without power equipment or special tools, but a single individual can often manage a smaller tank that has half the media and water of the larger tank.

Simplicity of equipment. Using two smaller filters rather than one very large one usually allows use of a more user-friendly small residential control valve rather than a large commercial assembly that is harder to service, harder to find parts for, and more complicated to program. Likewise, two smaller residential control valves are in many cases less expensive than a single commercial-sized control.

Redundancy. If a filter malfunctions and needs repair, you can bypass the faulty unit and still have water service to the residence through the remaining unit. You may have to limit your water consumption, but it’s sure better than having no water at all.

Here are some tank size equivalents, based on media needed.

A 1o” x 54″ filter can be replaced by two 8″ X 44″ filters to make a 1.5 cubic foot filter.

A 12″ x 52″ filter can be replaced by two 9″ X 48″ filters to make a 2.0 cubic foot filter.

A 13″ x 54″ filter can be replaced by two 10″ X 44″ filters to make a 2.5 cubic foot filter.

Larger units.

Two 12″ X 52″ filters can replace a 14″ X 65″ or a 16″ X 65″.

Two 13″ X 54″ units and replace a 18″ X 65″ filter.

Three 13″ X 65″ filters can substitute for a 21″ X 62″ filter.

There are, of course, many other possibilities.